All of the above It is the first step in histotechnology Step in tissue processing by which water from the tissue is removed after fixation B Will make microscopic tissue preparation transparent C Will merely improve refractive index of the tissue D All of the aboveFeb 03, 17 · Masking fluid, also known as liquid frisket, is a very handy tool for creating fine art, and is used to preserve white areas that would be too tiny or complex to paint around Masking fluid is especially important for highly pigmented mediums such as alcohol ink that will stain your art surface (or substrate)Also known as skill or technique, this is how a ninja converts it's chakra into other energy forms for combat To perform a jutsu, the ninja will bring out and release the two energies of chakra Physical and Mental/Spiritual By forming seals, the ninja is able to manifest the desired technique

Explosive Forming Of A Closed Shell Download Scientific Diagram

Stand-off technique in explosive forming is also known as

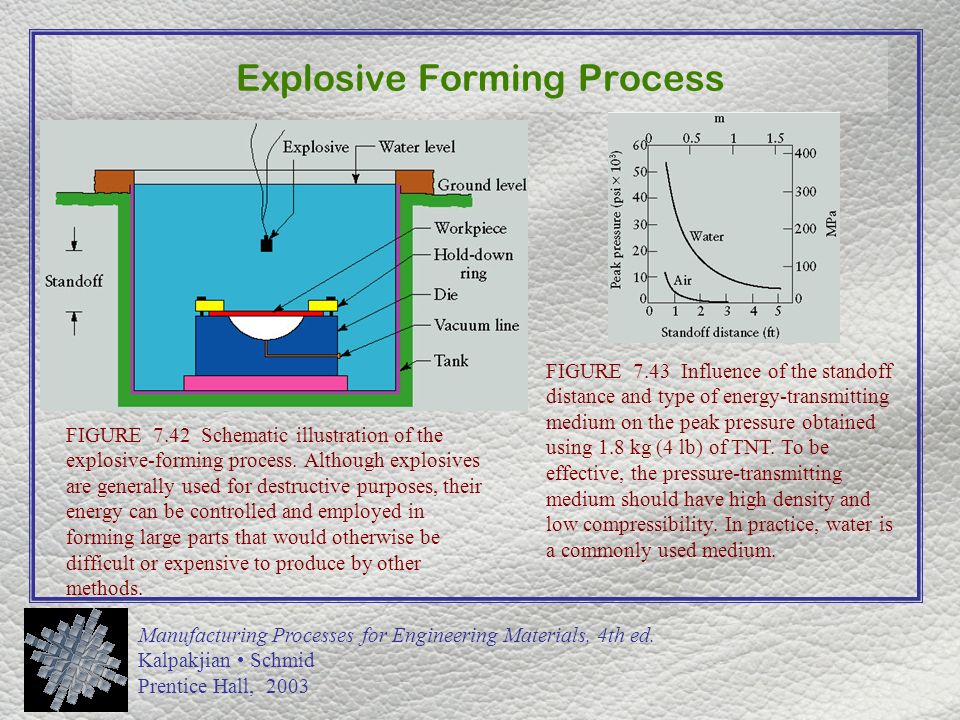

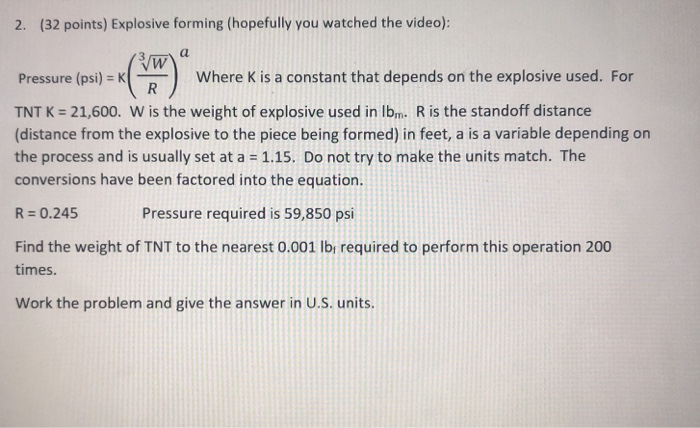

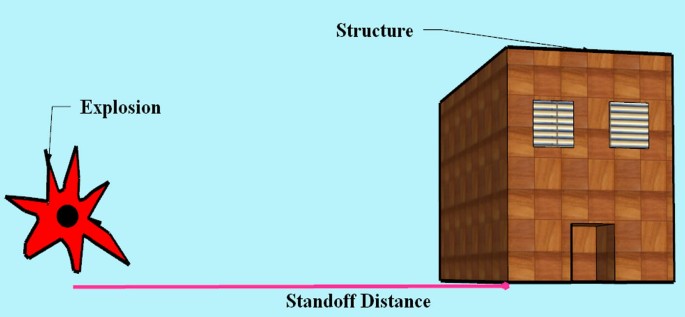

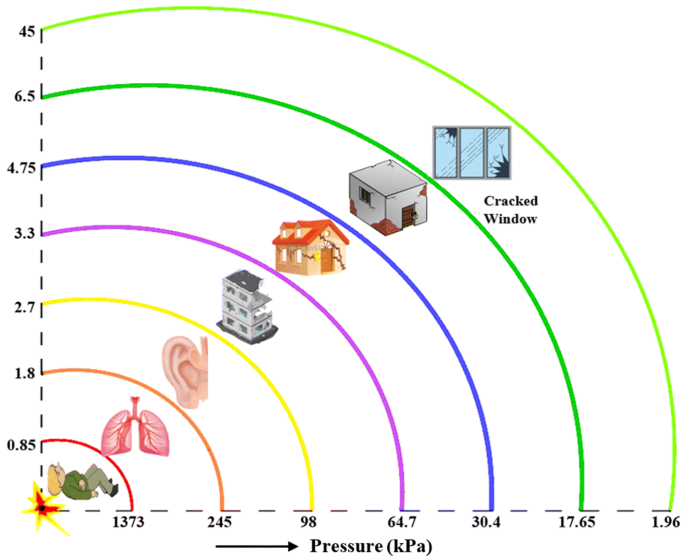

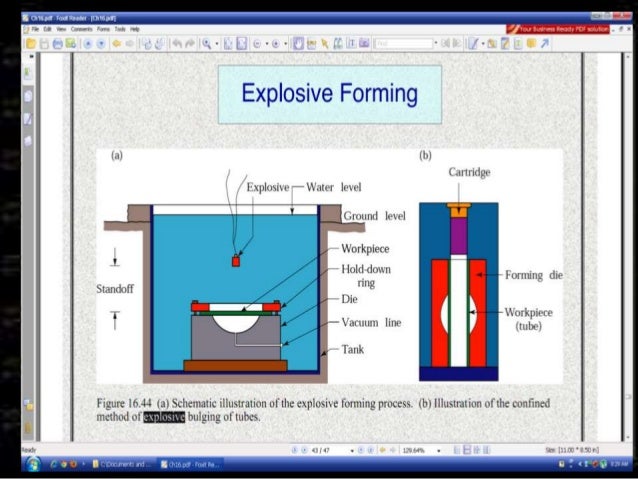

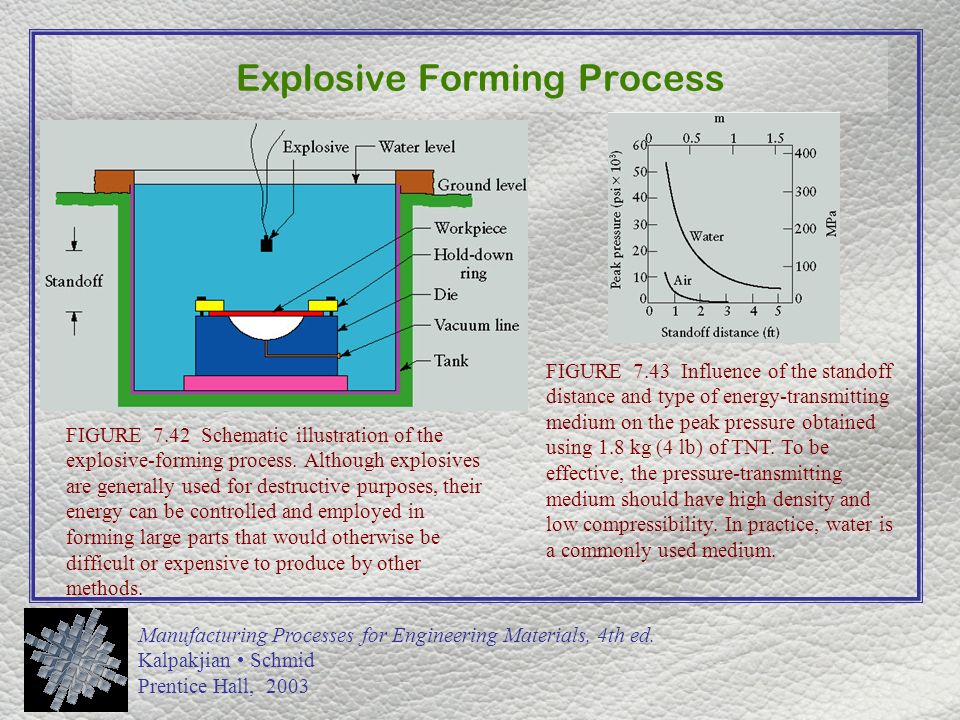

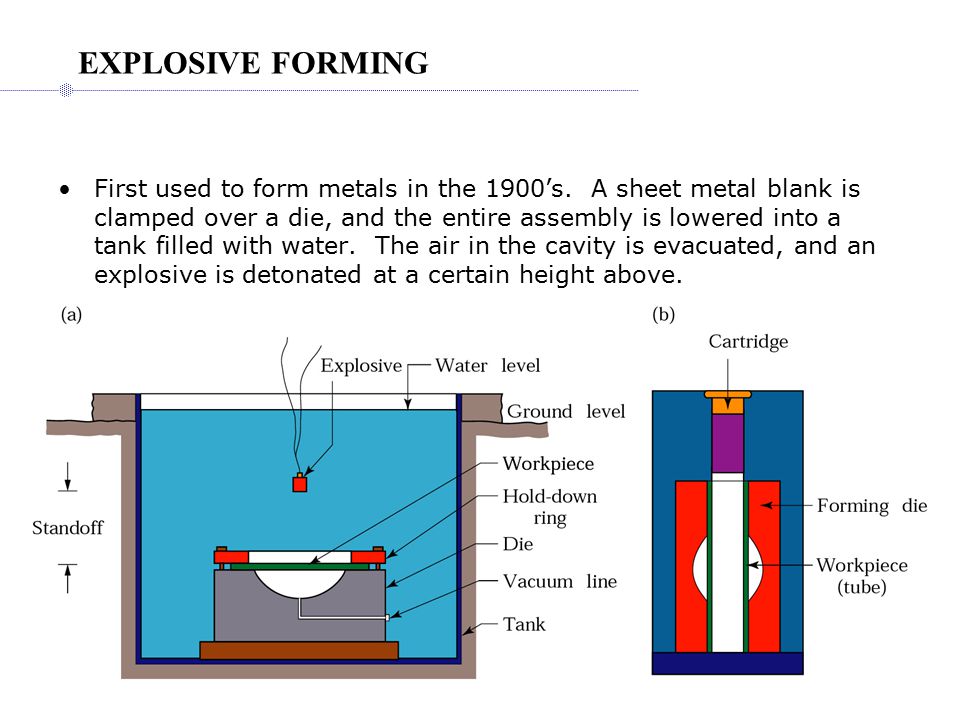

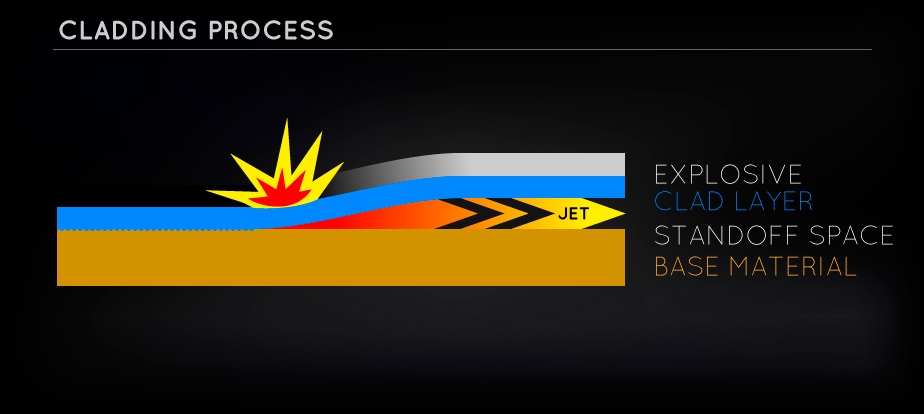

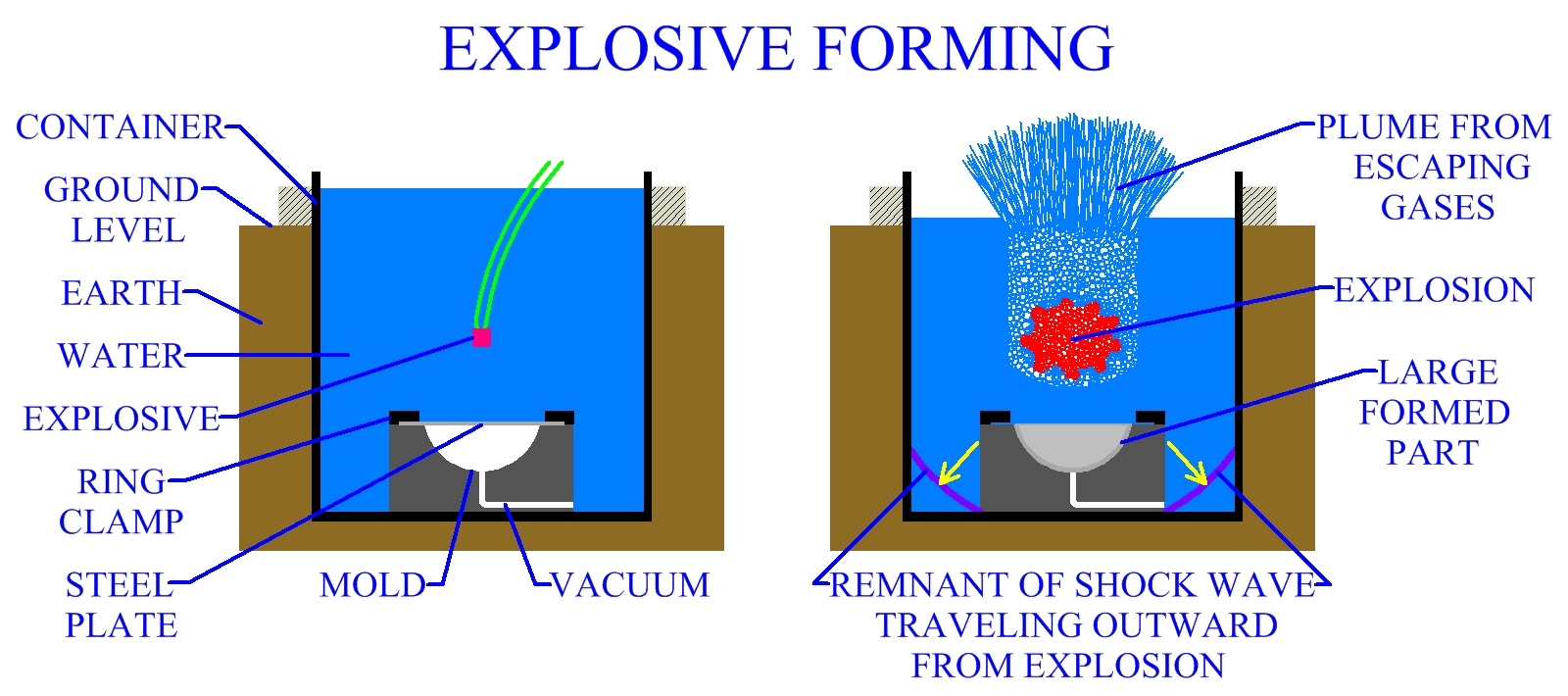

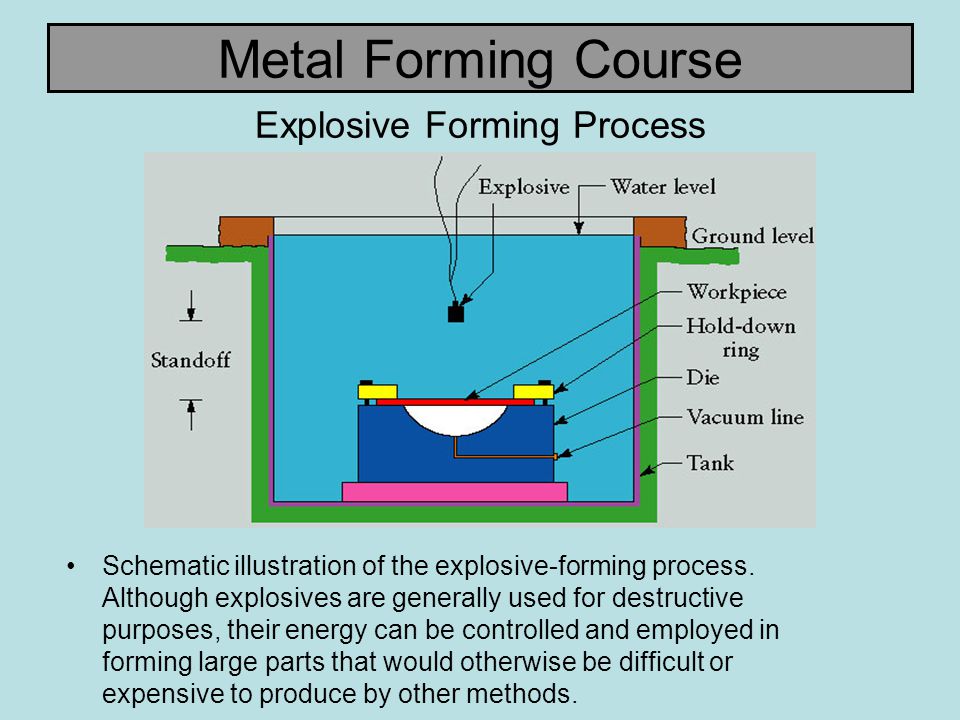

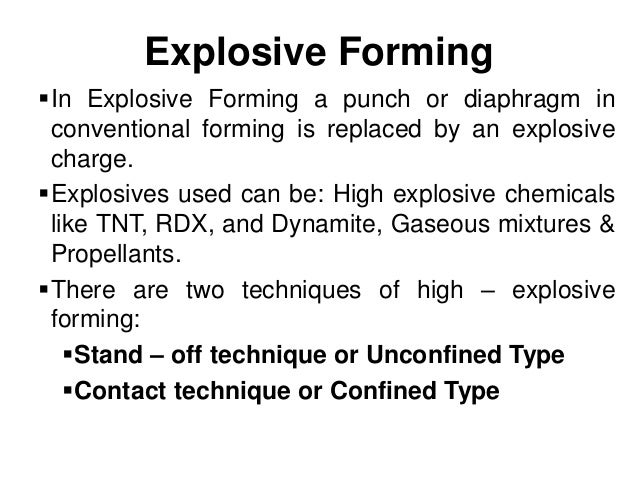

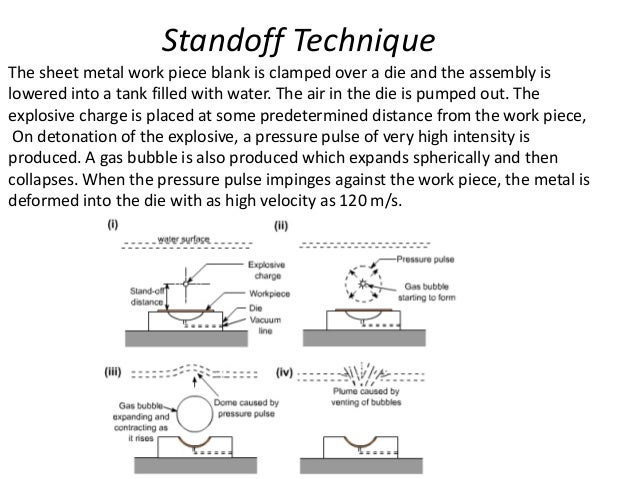

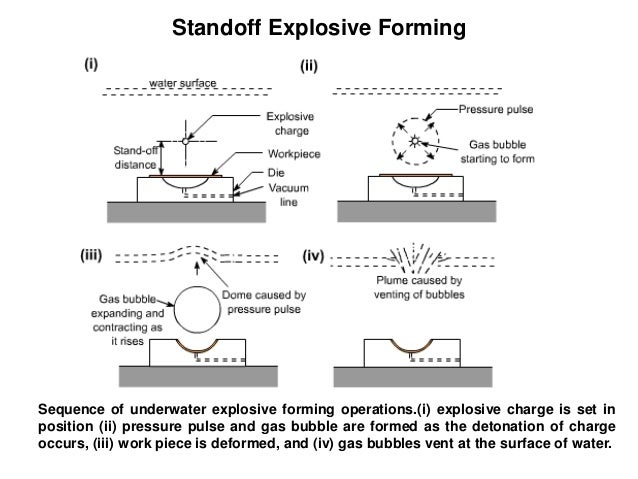

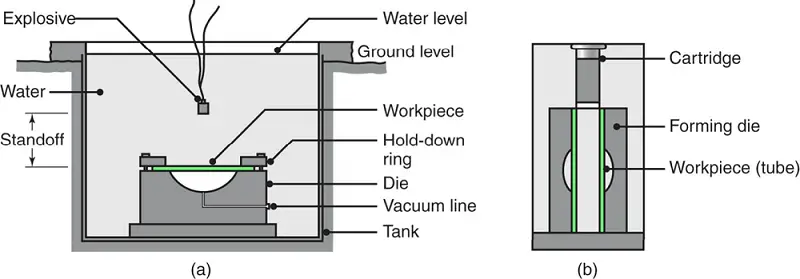

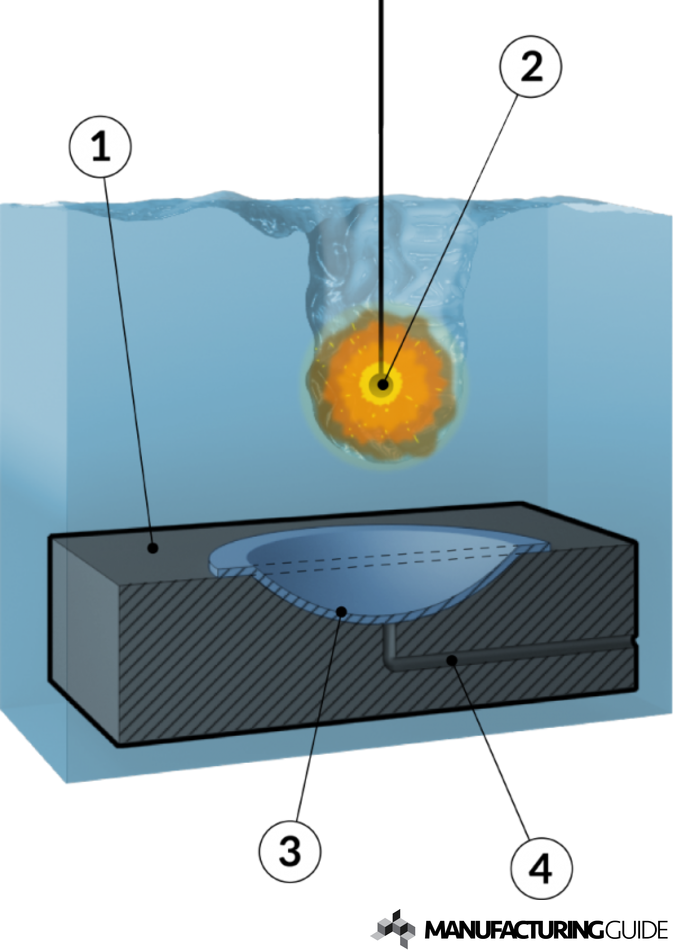

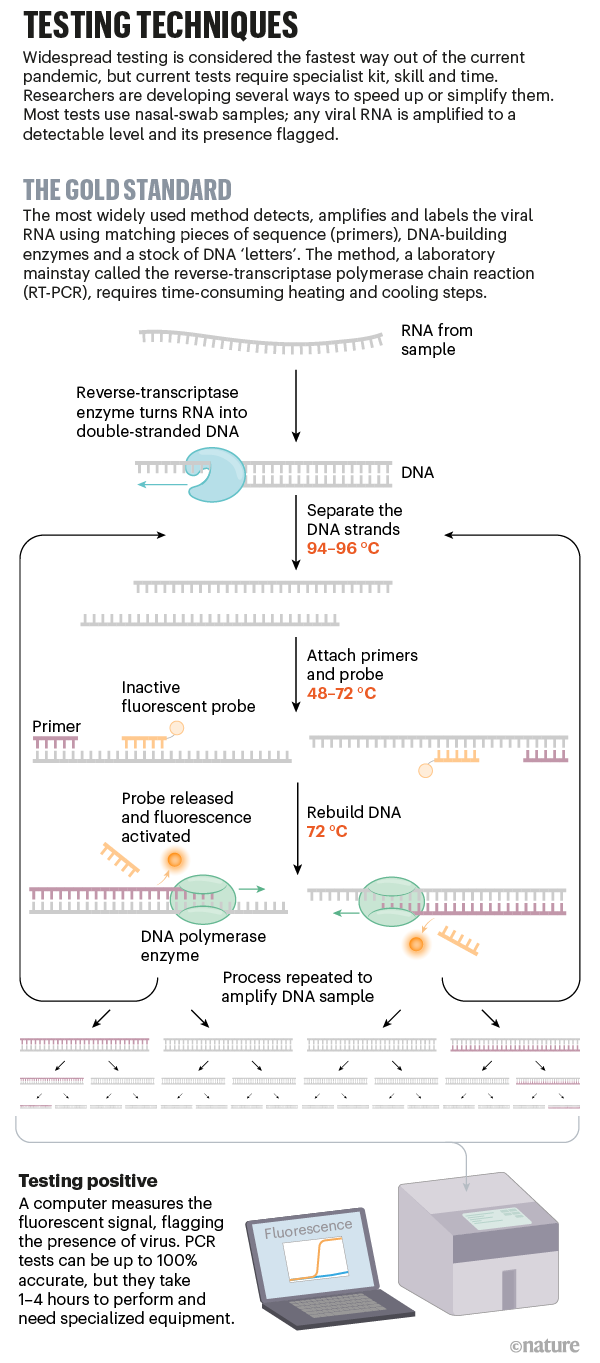

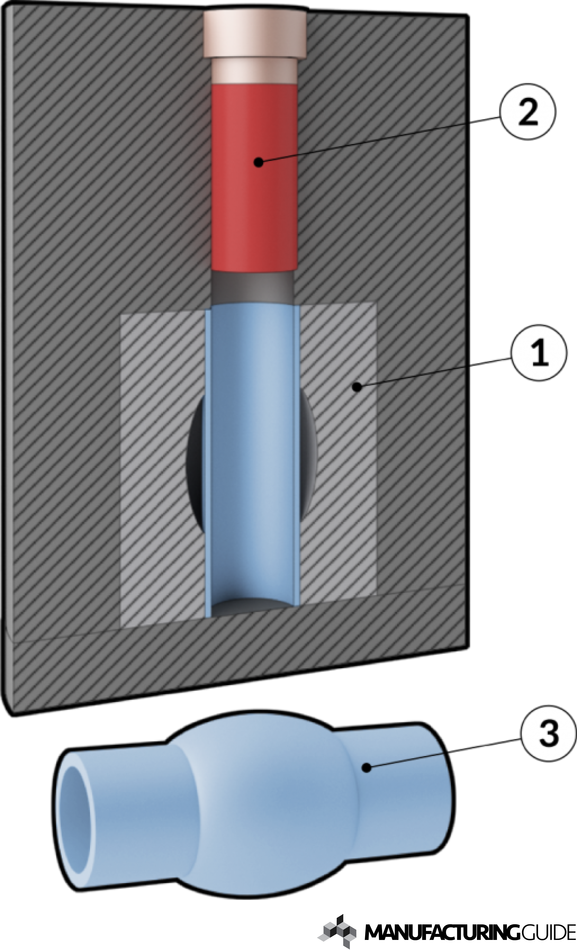

Stand-off technique in explosive forming is also known as-The explosives used are generally high – explosive chemicals, gaseous mixtures, or propellants There are two techniques of high – explosive forming stand – off technique and the contact technique Standoff Technique The sheet metal work piece blank is clamped over a die and the assembly is lowered into a tank filled with waterExplosive cladding is a cold 'pressure weld process (at room temperature)' It is a method to weld metals that cannot be welded by conventional processes, such as titaniumsteel, aluminiumsteel and aluminiumcopper It can also be used to weld compatible metals, such as stainless steels and nickel alloys to steel

Chapter 7 Sheet Metal Forming Processes Ppt Video Online Download

The most common explosive metalworking technique is explosive welding, also known as explosive bondingor explosive cladding This metalworking technique uses controlled detonations to force dissimilar metals into a highquality, metallurgically bonded jointA technique that can be used to cut metal and a wide variety of softer materials Also known as the "Cookiecutter" die Here the cutting die is fashioned from hardened steel strips, known asShaped and will retain that shape after forming, much like clay Putties normally contain mostly RDX explosive, but may include some PETN (Semtex, for example) 221 RDX RDX, an initialism for Research Department Explosive, is an explosive nitroamine widely used in military and industrial applications RDX is also known as cyclonite, hexogen

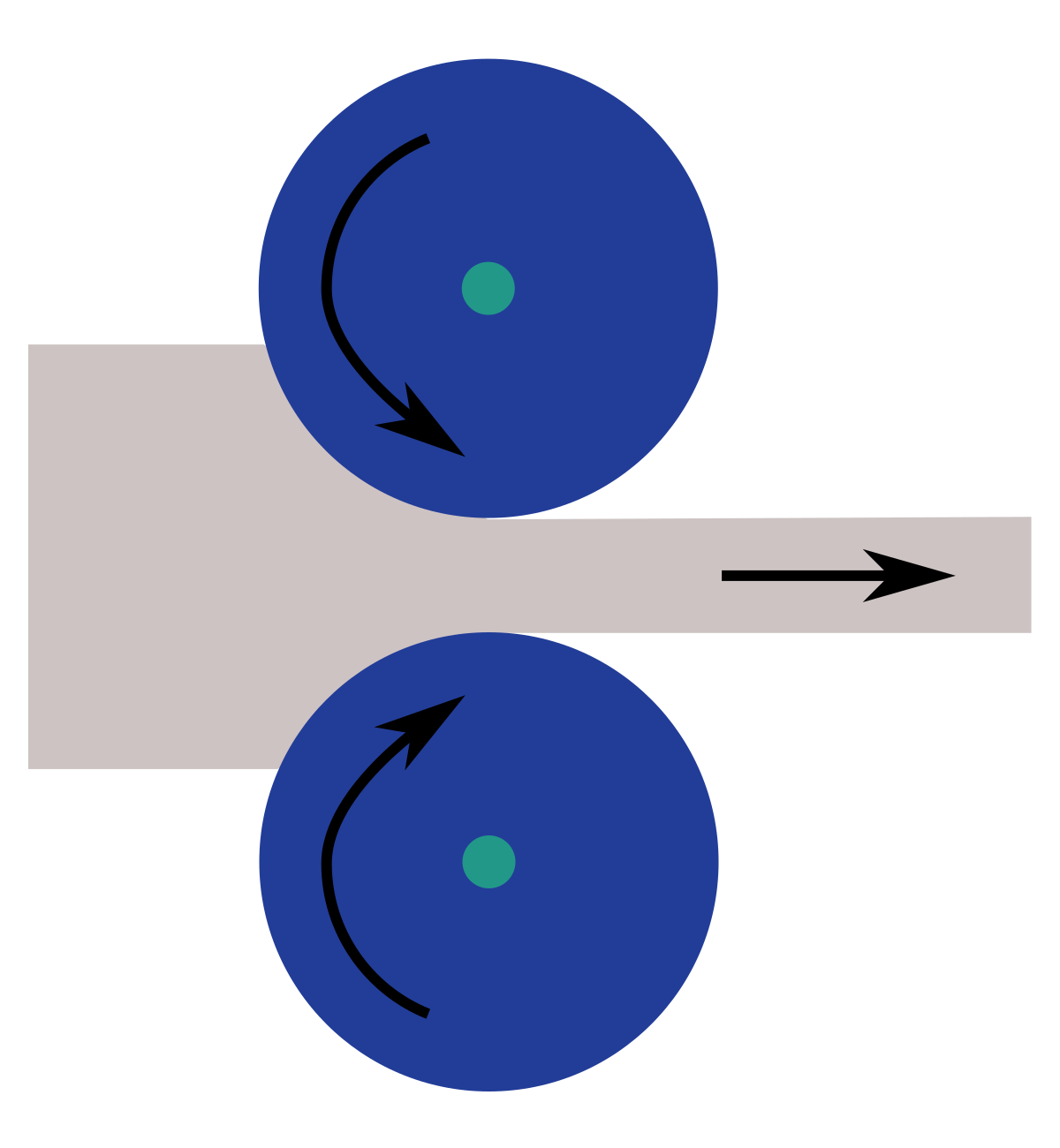

The range between the lower and upper explosive limits is called the explosive range of the gas (or vapor) Table 71 shows the flashpoint, LEL, UEL, and ignition temperature for a few of theFeb 11, 14 · Metal spinning, also known as spin forming or spinning or metal turning most commonly, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part Spinning can be performed by hand or by a CNC latheExplosive forming, is distinguished from conventional forming in that the punch or diaphragm is replaced by an explosive charge The explosives used are generally high – explosive chemicals, gaseous mixtures, or propellants There are two techniques of high – explosive forming Stand – Off Technique The Contact Technique Explosive Forming

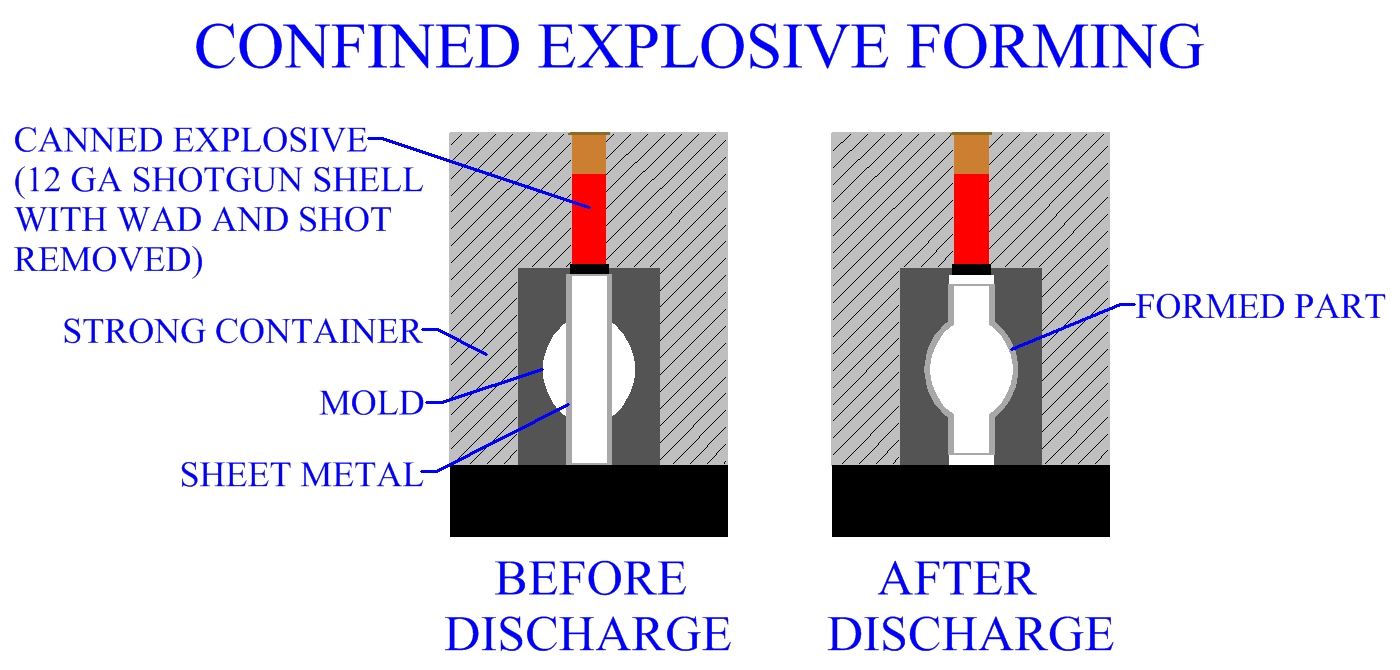

Jan 03, 18 · Tetramethylene diperoxide dicarbamide (TMDD) is a cyclic organic peroxide compound of fourteen atoms, whose scientific name is 1, 2, 8, 9tetraoxa4, 6, 11, 13tetraazacyclotetradecane5, 12dione TMDD is also known as a homemade explosive because its precursors are household or consumer productsApr 07, · Q5 Explain Explosive forming with neat sketchsketch also explains it's two techniques left hand side diagram is for a) stand off technique right hand side a) contact technique Electro hydraulic forming (EHF) also known as electro spark forming, is a process in which electrical energy is converted into mechanical energy for the formingContact technique Standoff Technique In this assembly the sheet metal work piece blank is clamped over a die and the assembly, is lowered into a tank filled with water, air in the die is

2 32 Points Explosive Forming Hopefully You Chegg Com

Explosive Forming Of A Closed Shell Download Scientific Diagram

Dec 31, 16 · Electro hydraulic forming (EHF), also known as electro spark forming, is a process in which electrical energy is converted into mechanical energy for the forming of metallic parts A bank of capacitors is first charged to a high voltage and then discharged across a gap between two electrodes, causing explosions inside the hollow work piece, which is filled with some suitableBecause of our unique vacuum explosion technique, we can handle all type of material combinations and projects of different sizes This technique is designed to protect the environment and to serve our clients Preface Explosive cladding is also known as explosion welding It is the bonding of two or more dissimilar metals with the aid ofJan 11, 16 · Forming, also known as "metal forming," includes a wide range of manufacturing processes in which metal is deformed into a required shape by the application of suitable stresses To make the metal plastically deformed, forces must be applied that are greater than the yield strength of the metals The magnitude of the compression, stretching or bending in the material,

Construction Of Spherical Tanks By Explosive Method Explosive Hydroforming Youtube

A Critical Review Of Blast Wave Parameters And Approaches For Blast Load Mitigation Springerlink

Sheet forming Sheet metal forming involves forming and cutting operations performed on metal sheets, strips, and coils The surface areatovolume ratio of the starting metal is relatively high Tools include punch, die that are used to deform the sheets Classification of basic sheet forming processes Bending Deep drawing shearingThe explosive operation is completed in about sec, implying a power of 107 MW This indicates that the last case results in not only the most compact but also the most powerful machine High velocity forming operations, viz, explosive and electric discharge forming, are based on the foregoing principleSwaging (/ ˈ s w eɪ dʒ ɪ ŋ /) is a forging process in which the dimensions of an item are altered using dies into which the item is forced Swaging is usually a cold working process, but also may be hot worked The term swage may apply to the process (verb) or

A Critical Review Of Blast Wave Parameters And Approaches For Blast Load Mitigation Springerlink

In These Forming Processes Large Amount Of Energy Is Applied For A Very Short Interval Of Time Many Metals Tend To Deform More Readily Under Extra Ppt Download

DOMERAPI Dynamics of an arc volcano with extruding lava domes, Merapi (Indonesia) from the magma reservoir to eruptive processes DOMERAPI is an international scientific research project funded by French Agence Nationale de la Recherche (ANR12BS) with support of Institut de Recherche pour le Développement, focused on the study of Merapi volcano (Java, Indonesia)May 27, 21 · The modern manufacturing process is also known as a nontraditional manufacturing process in which sharp cutting tools are not used as in the traditional manufacturing process In these modern manufacturing processes, various techniques involving mechanical, thermal, electrical chemical energy or combinations of these are used to create theHigh Energy Rate Forming Processes pnxk2w0yr94v Download & View High Energy Rate Forming Processes as PDF for free

Explosive Forming

List Of Techniques Used By Vegeta Dragon Ball Wiki Fandom

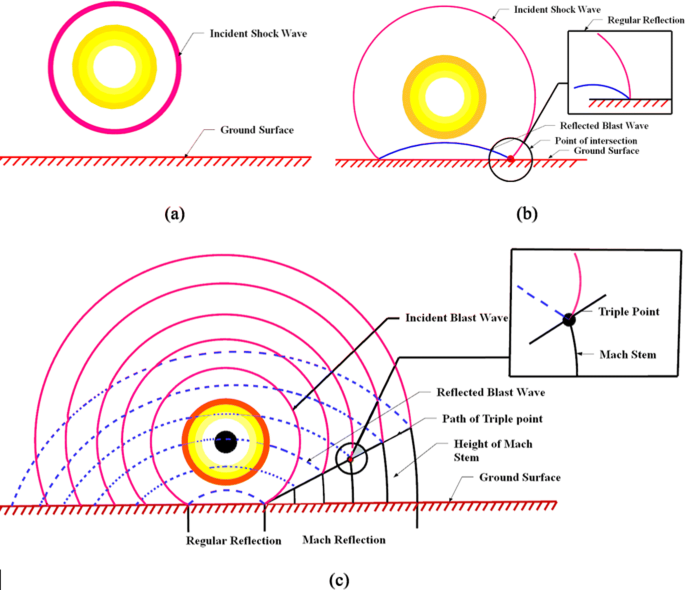

Jan 19, 12 · Standoff Technique The sheet metal work piece blank is clamped over a die and the assembly is lowered into a tank filled with water The air in the die is pumped out The explosive charge is placed at some predetermined distance from the work piece, see Fig 91 On detonation of the explosive, a pressure pulse of very high intensity is producedOther considerations, such as anchoring nonstructural components inside the building, are also design objectives that require special attention, as is protection of emergency services The size of the explosive threat will determine the effectiveness of each of these protective features and the resources necessary to protect building occupantsJan 12, 15 · In contrast to conventional sheet metal forming processes, the techniques involving high velocity forming would serve as a "frictionless punch" to deform the thin sheets and would be much more effective in terms of energy transfer (KE∝v 2)Although this idea is intriguing and the process is quite sophisticated, the evolution of microstructure and texture during such a process

Chapter 7 Sheet Metal Forming Processes Ppt Video Online Download

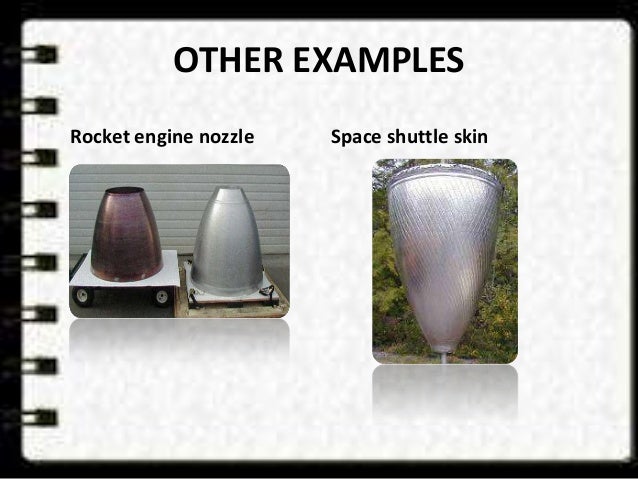

Explosive Forming An Overview Sciencedirect Topics

IR LIBS, also known as LITE, or LaserInduced Thermal Emission, has greater capabilities to identity target compounds than traditional LIBS systems IR LIBS/LITE is a standoff detection technology that can identify target compounds in a hazardous environment byI'm glad you asked, but I'm even more glad the Youtube video description provided an explanation Explosive hydroforming, also known as HERF (High Energy Rate Forming) or exploform, is a striking alternative to the more traditional process of metal hydroformingDec 16, · Metal spinning, also known as spin forming or spinning or metal turning most commonly, is a metalworking process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part Spinning can be performed by hand or by a CNC lathe Metal spinning does not involve removal of ma

Manufacturing Technology I Ppt Download

Home Smt Holland Shockwave Metalworking Techonologies Shockwave Metalworking Technologies Holland

Aug 04, 04 · Flattens against the target on impact then explodes The armor is not penetrated, but the shock wave knocks a scab off the inside of the armor plate which bounces around the interior of the target at high speed Unlike HEAT, HESH projectiles have a secondary antipersonnel capability Also known as high explosive squash head (HESH)Explosive Forming Explosive forming, is distinguished from conventional forming in that the punch or diaphragm is replaced by an explosive charge Explosives used are generally high – explosive chemicals, gaseous mixtures, or propellants There are two techniques of high –explosive forming Stand –off technique Contact techniqueMetal spinning, Explosive forming & Magnetic pulse forming Metal spinning • Metal spinning, also known as spin forming or spinning or metal turning most commonly, is a metal working process by which a disc or tube of metal is rotated at high speed and formed into an axially symmetric part Spinning can be performed by hand or by a CNC machine

Herf Electromagnetic Induction Electric Current

Explosive Forming

Tephra is also known as pyroclastic material—volcanic material that erupted explosively and flew through the air for some distance before landing on the ground Tephra results from pyroclastic eruptions, which means explosive volcanic eruptions that hurl material into the air There are several types of pyroclastic material, or tephraA sensor that emits an infrared beam to a receiver forming an invisible link that, when broken, acts as a trigger to alternative conventional munition disposal techniques Explosive engineering techniques developed to facilitate Conventional Munition Disposal without resorting to high Also known as flashback Glossary of EOD terms1 Hashirama Senju 8 Nawaki Nawaki was the grandson of Hashirama Senju and the brother of Tsunade His dream was to become Hokage, like his grandfather Very little is known about his abilities, but Nawaki died in the Second Great Ninja War, after running into an explosive

What Is Explosion Welding Fastener Engineering

High Energy Rate Forming Of Sheet Metal

Dropraising also known as 'Longhole Raise blasting' or 'Upside down Raising', whereby an excavation is completely predrilled over the full length and then charged from the top and blasted from the bottom in practical lengths for an effective advance per blast This technique has been practised in SouthMar 15, 18 · Standoff Explosive Forming Advantages Shock wave is efficiently transmitted through water and energy is transmitted effectively on the work Less noise Less probability of damage to work Large and thick parts can be easily formed Economical, when compared to a hydraulic press The process is versatile – a large variety of shapes can be formed, no limit to theJun 24, 21 · Explosive hydroforming techniques fall into two basic categories Although both methods function according to the same general principles, they rely on very different placement of the explosive charge within the forming chamber Standoff Method With the Standoff Method, the explosive charge is used in conjunction with an intervening medium In most hydroforming

Explosive Forming Of A Closed Shell Download Scientific Diagram

Chapter 3

Explosive Forming In this technique the punch in conventional forming is replaced by an explosive charge There are two techniques of high – explosive forming Stand – off technique;However the mechanical behavior of metals is generally not highly rate from CS MISC at NIT RourkelaThermoformed (or vacuum formed, as it is also known) plastic is THE stateoftheart process for producing panels, covers, bezels and housings that are attractive and durable — yet lightweight and affordable Attractive Thermoformed plastic parts can be produced in a nearly unlimited variety of base materials, finishes, colors and textures

High Energy Rate Forming Of Sheet Metal

A Critical Review Of Blast Wave Parameters And Approaches For Blast Load Mitigation Springerlink

There are two techniques of high – explosive forming Stand – off technique;Apr 08, 21 · What the hell is explosive hydroforming?The invention relates to methods for producing explosive compositions formed by ammonium nitrate and fuel, also known as ANFO (Ammonium nitrate/Fuel Oil), and to the explosive compositions formed by bulk emulsion and ANFO, also known as heavy ANFO The invention especially comprises two types of method for using highdensity ammonium nitrate in the production of said explosive

How To Make A Building Blast Resistant Architect Magazine

Characteristics Of Metals Important In Sheet Forming Ppt Video Online Download

May 04, 21 · Explosive forming, is distinguished from conventional forming in that the punch or diaphragm is replaced by an explosive charge The explosives used are generally high explosive chemicals, gaseous mixtures, or propellants Principle of High Energy Rate Forming The technique uses the energy generated by an explosive detonation to form the metalContact technique Standoff Technique In this assembly the sheet metal work piece blank is clamped over a die and the assembly, is lowered into a tank filled with water, air in the die is pumped out Explosive charge is placed at some predetermined distance from the work piece On detonation of the explosive, a pressure pulse of very high intensity is produced Gas bubble is alsoTrivia " C4 ", also known as Composition C4 is the latest of the Composition C plastic explosives that has been used since the 1950s due to its effectiveness It is so stable that only a blasting cap will detonate it, if lit on fire it will not explode (it will burn at a very high temperature) and can safely be used for cooking (though this

Tunnels And Underground Excavations History Methods Uses Facts Britannica

Chapter 3

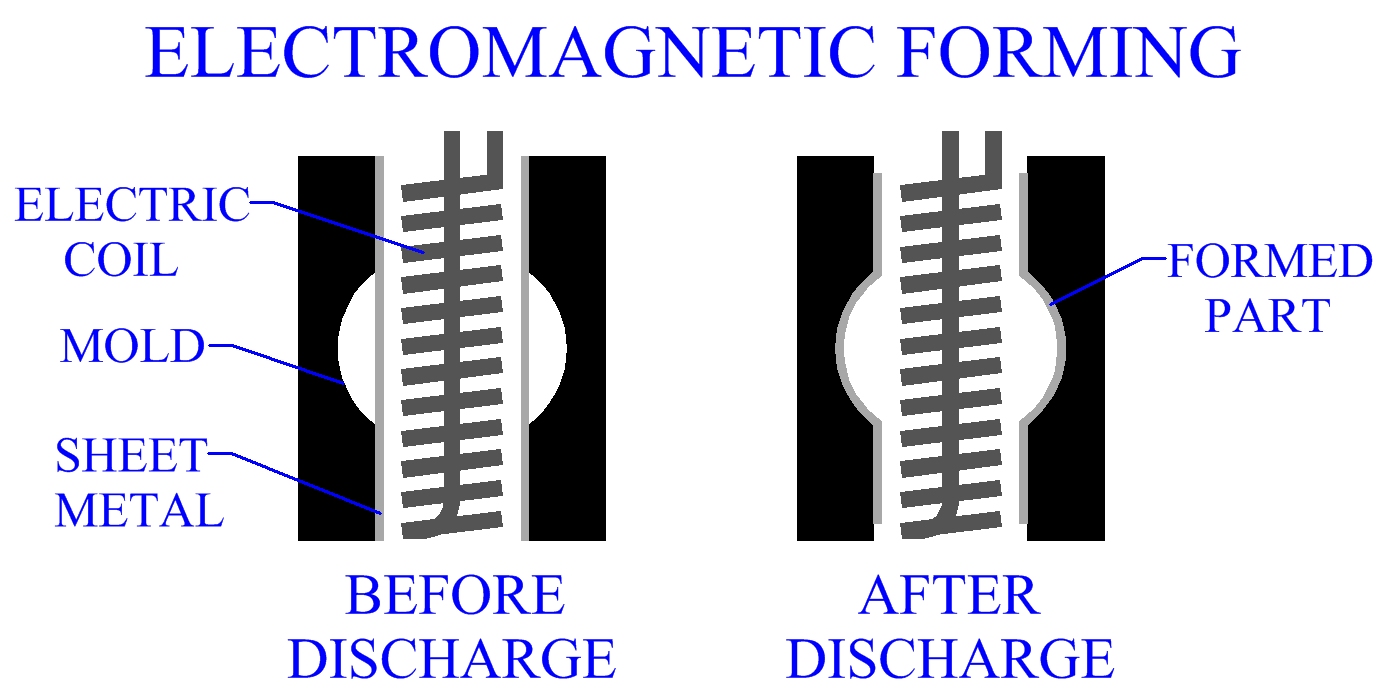

The s pecial forming processes are now in common use and can be subdivided into three major alternative forming techniques (1) magnetic forming, (2) highenergyrate forming, and (3) powder metallurgy processing (also known as sintering) The magnetic forming processes induce sudden magnetic forces about the object to be shaped, causing it toCAvity Containers also known as shape charges, and are the geometric cavity and suitable liner with standoff for deep penetration into a steel or concrete 'object It normally consists of a container, cavity liner (cone), an explosive charge, and standoff distance

Unit 5b High Velocity Forming Methods

What Is Metal Stamping A Guide To Processes Steps And Types Of Presses

Explosive Forming An Overview Sciencedirect Topics

Shaped Charge Wikipedia

New Doc 21 04 09 04 46

Amt Module 5 Explosive Forming Process Youtube

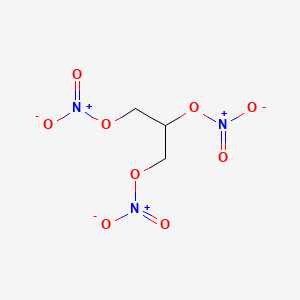

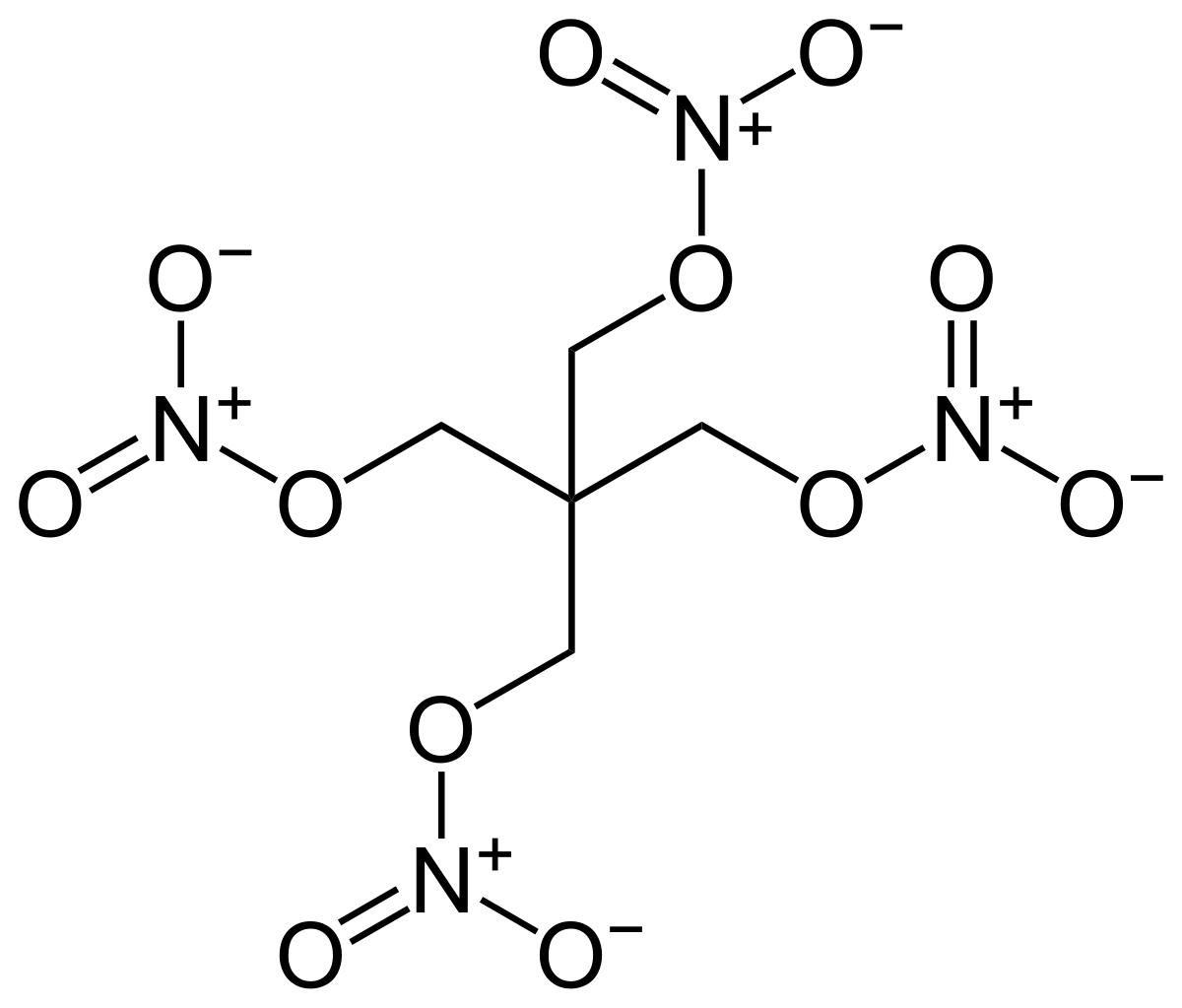

Nitroglycerin C3h5 No3 3 Pubchem

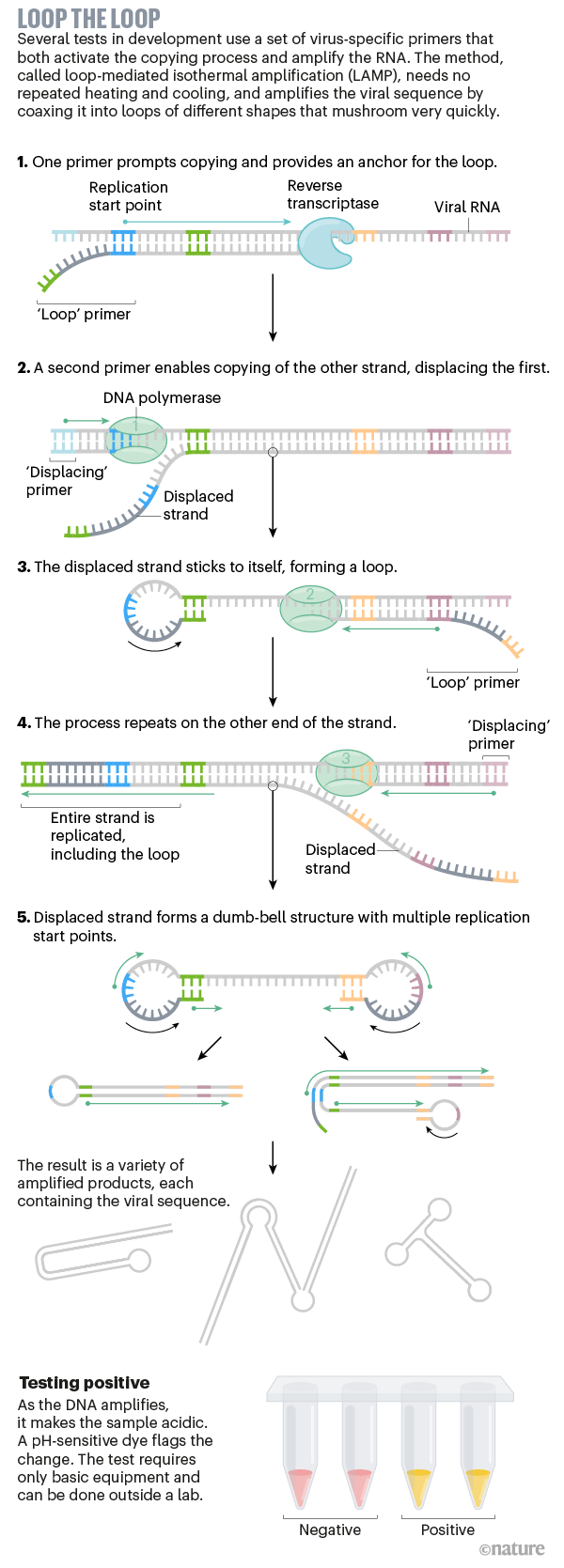

The Explosion Of New Coronavirus Tests That Could Help To End The Pandemic

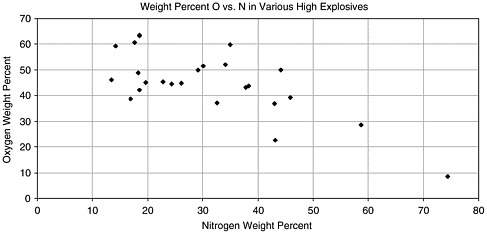

4 Chemical Characteristics Of Bombs Existing And Potential Standoff Explosives Detection Techniques The National Academies Press

Schematic Diagram Of A Stand Off Explosive Forming Process Download Scientific Diagram

High Energy Rate Forming Of Sheet Metal

Explosive Hydroforming Youtube

Cyclonite C3h6n6o6 Pubchem

Unconventional Forming

High Energy Rate Forming Of Sheet Metal

Explosive Forming An Overview Metalwebnews Com

Review Of Explosive Detection Methodologies And The Emergence Of Standoff Deep Uv Resonance Raman Gares 16 Journal Of Raman Spectroscopy Wiley Online Library

Stand Off Raman Spectroscopy A Powerful Technique For Qualitative And Quantitative Analysis Of Inorganic And Organic Compounds Including Explosives Springerlink

Schematic Examples Of Typical Explosive Forming Operations A Use Of Download Scientific Diagram

Unit 5b High Velocity Forming Methods

Confined Explosive Forming By Bella Ami

Working Media Based High Velocity Forming I Fg

Explosive Forming An Overview Sciencedirect Topics

Review Of Explosive Detection Methodologies And The Emergence Of Standoff Deep Uv Resonance Raman Gares 16 Journal Of Raman Spectroscopy Wiley Online Library

History Scope And Development Of Biotechnology Book Chapter Iopscience

Sheet Metal Forming Processes And Equipment Machinemfg

4 Chemical Characteristics Of Bombs Existing And Potential Standoff Explosives Detection Techniques The National Academies Press

Qcl Primer History Characteristics Applications Lasers Photonics Handbook Photonics Marketplace

Qcl Primer History Characteristics Applications Lasers Photonics Handbook Photonics Marketplace

Home Smt Holland Shockwave Metalworking Techonologies Shockwave Metalworking Technologies Holland

Schematic Diagram Of A Stand Off Explosive Forming Process Download Scientific Diagram

Sodium Facts Uses Properties Britannica

Explosive Forming Engineeringclicks

Spring Back Effect In Herf Is A Large B Small C Negligible D None Of Above 6 Course Hero

Pentaerythritol Tetranitrate Wikipedia

Fracking 101 Nrdc

Explosive Forming Of A Closed Shell Download Scientific Diagram

Explosive Forming Shock Wave Vacuum Tube

Explosive Forming Of Plates Find Suppliers Processes Material

Shaped Charge Wikipedia

Explosive Forming

How Does Explosive Forming Of Steel Work Quora

Explosive Forming Engineeringclicks

Explosive Forming An Overview Metalwebnews Com

Electro Hydraulic Forming Diagram Working Advantages Applications

Explosive Forming An Overview Sciencedirect Topics

The Explosion Of New Coronavirus Tests That Could Help To End The Pandemic

Explosive Forming Of Pipes Find Suppliers Processes Material

Ppt Electro Hydraulic Forming Powerpoint Presentation Free Download Id

Shaped Charge An Overview Sciencedirect Topics

Electro Hydraulic Forming Diagram Working Advantages Applications

Explosive Hydro Forming Hermetic Solutions Group

Explosive Forming

Rolling Metalworking Wikipedia

0 件のコメント:

コメントを投稿